Design situation and brief

Plastic waste is one of, if not the most catastrophic problem plaguing waterways today. As someone who enjoys the outdoors and is lucky enough to experience Sydney’s beautiful waterways, I sought, throughout 2021 and the start of 2022, to apply my passion for design to create a prototype to help make my small dent in this global issue.

Throughout school, my friends and I eagerly anticipated the holidays when we could finally be rid of assignments and go fishing. We weren’t particularly serious fishermen, exploring various waterways from rivers to harbours and jetties. However, over our fishing trips, I observed that floating plastic waste often accumulated in these locations, concentrated in areas that were difficult to navigate, such as underneath boardwalks, around drainage pipes, and eddies. Naturally, being hard to access, these areas are hard to clean, and over time, they only collected more and more plastic waste.

In recognition of this issue, my project was purposed with creating a remote control device: a small and portable vessel that could be remotely operated to navigate these difficult areas and collect floating plastic waste.

Ideation

Here are some sketches of preliminary design concepts. An essential element of the design process is the ability to communicate ideas to not only others but also your future self as the blurry notion of the final product slowly becomes clearer. Hopefully, these crude and primitive sketches provide some insight into the next stages of development.

These were some of the first sketches I drew, hoping to capture the fundamental shape and vibe of the device. Two basic functions were the primary points of consideration: a way to move and a way to collect waste. The top left concept captures waste using a net, functioning in a somewhat similar fashion to a child capturing fireflies at night with a net. The top right concept uses a rotating tube with prongs/hooks to collect waste, like a rotary harrow.

Below are some different ways in which movement and steering could be achieved. Additionally, I was also trying to picture how I could position all the electronics in a space-efficient manner that conceals them from the water, which may damage them.

Here is a more in-depth exploration into the intake mechanism, from the rotating prongs to an adjustable and removable net. Ultimately, the rotator method was chosen since the net's collection of plastic waste would increase drag in the water, counteracting the device's ability to move, much like how one feels resistance when pulling a bucket through water.

Final sketch

Computer Aided Design (CAD)

When implementing the design into a CAD model, I had two approaches to the device’s overall body, which is comprised of two 'pontoons'. The first approach (left) uses a single pontoon body, which is smaller and more compact, and is easier to print given the size of available 3D printers. The second option (right) splits the body into two parts, which provides more storage area but would be significantly heavier and more time-consuming to print.

Below is an exploded view of the models, providing a clearer visualization of how certain components are fitted together. Considering time constraints, material usage, and portability, I moved forward with the single-body design.

This orthographic drawing helps to contextualize scale, showing the details and dimensions precisely. It allows me to gauge the exact specifications of the design when moving forward.

System Design

Functional requirements

Two motors for steering

One motor for waste intake mechanism

Bluetooth connection

Movement

Right motor activation conducts a left turn

Intake

Both motors on to move forward

One possible intake mechanism involves a rotating tube with prongs or hooks to ‘gather’ waste into a storage area.

Circuit Diagram

Left motor activation conducts a left turn

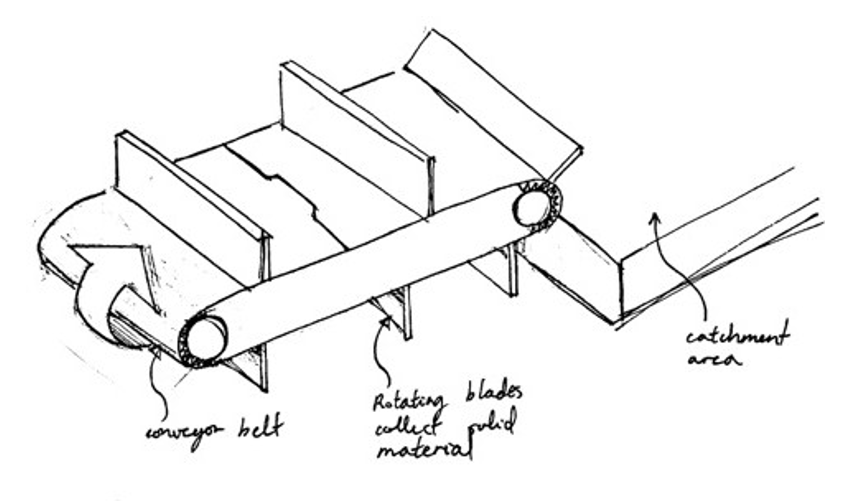

Another possible intake mechanism is a conveyor belt that lifts waste out of the water and ‘dumps’ it into a storage area.

This circuit diagram helps to provide a graphical representation the basic system for the device’s function

L298N Motor Driver: The device’s movement depends on two motors so the L298N motor driver provides the necessary control for both speed and direction.

HC-05 Bluetooth Module: The HC-05 allows any phone that supports bluetooth to connect and control the device. Since the function of my device only requires it to receive data from the phone, the master-slave mode is not necessary.

Arduino Uno Microcontroller: The Arduino microprocessor provides me the unique ability to use the Arduino bluetooth controller application as a means of operation which is available on most phones.

The L298N motor driver can only run two motors and thus, an extra pinout and MOSFET was integrated to run a third motor for the rotator intake mechanism.

A voltage divider is a passive linear circuit that produces an output voltage that is a fraction of the input voltage. I will need to use a voltage divider since the HC-05 module can only handle a supply voltage of 3.3V even though the Arduino operates at 5V. Using three 1000-ohm resistors, I constructed a voltage divider to take a fraction of the 5V.

Program

In the code, I established four distinct cases to represent four modes of movement: forward, backward, right turn, and left turn. During the initial testing phase, upon inputting 'F', the green and blue LEDs were programmed to illuminate. When 'B' was entered, the yellow and orange LEDs were set to turn on. Inputting 'R' triggered the activation of the blue and yellow LEDs, while 'L' resulted in the illumination of the green and orange LEDs. Each of these LEDs corresponded with one of the movement motors and the direction in which they were rotating.

Case ‘F’: both motors turning clockwise

Case ‘R’: left motor clockwise and right motor anticlockwise

Case ‘B’: both motors turning anticlockwise

Case ‘L’: right motor clockwise left motor anticlockwise

Bluetooth pairing and control configuration

The Arduino Bluetooth Controller application allows the Arduino board to be configured and controlled via bluetooth. Given the prevalence of mobile technology, using this interface promotes accessibility and also user-friendliness.

Production

Wiring

Once the optimal configuration and arrangement of wiring from the breadboard were established, the connections were soldered into place. Furthermore, a compact yet easily removable and deconstructible chassis was fabricated to house all electrical components. This design not only prioritised space efficiency but also ensured the ability to replace any damaged components if necessary.

Assembled

The switch and batteries were positioned on the right side of the raft. The dual-switch setup was implemented to ensure continuous power supply: when one set of batteries depleted, the switch could be toggled to activate another power source, allowing time for replacement of the depleted batteries.

The intake motor is attached to the rotator via a custom motor housing. This motor can be removed easily by unscrewed the nut that attaches it to the mount.

3D Printing

Using an AnyCubic Chiron printer, each component was individually printed from polyactic acid filament (PLA), a strong and eco-friendly material that is biodegradable and synthesised from plant-based materials. During the print, PLA is melted in order to form the desired shape but this means that as the model cools, the material expands reducing accuracy of the intended dimensions. After printing, chiselling and sanding was required to mitigate these inconsistencies and also to discard of any residual support structures.

Rotator

The intake mechanism was made using a PVC pipe and vinyl tubing fashioned into looped prongs. When rotated inward, these prongs functioned as a "gathering" mechanism, directing waste into a designated storage area. The flexible nature of the vinyl tubing facilitated the intake of objects of varying sizes, while still maintaining sufficient structural integrity to provide the necessary friction for effective collection.

The storage area consisted of a net specifically designed to hook onto the small loops inside the device's body. This allows for the drainage of water, ensuring that only solid materials are captured, thereby reducing the weight the device's load.

Underneath the lid is a layer of waterproofing sealant tape. The tubes that allow for wires to be transported to other locations on the raft are also watertight. One tube runs to the intake motor, one to the battery, and one to a movement motor.

The electronic housing is located on the left side of the raft. The shelf structure of the housing allows for the removal any specific component.

Testing

Movement

Intake

Looking ahead…

This project was undertaken during the COVID-19 lockdown period and consequently much of the testing could not be conducted in a field location as intended. Thus, testing was conducted in the controlled location of a pool where the device, whilst showing varying degrees of success, revealed numerous areas that could be refined. However, these could not be implemented in time for the project’s submission. The design process is underpinned by a continuing need to innovate and improve and with this design concept, there is endless possibility for future development.